INCREASED PLANT THROUGHPUT

Reduced pressure drop for increased plant throughputOverview

Aughinish Alumina Ltd wanted to reduce pressure losses of combustion Air flow in order to increase furnace throughput – and plant output.

Problem

Aughinish Alumina Ltd wanted to reduce pressure losses of combustion Air flow in order to increase furnace throughput and therefore plant output.

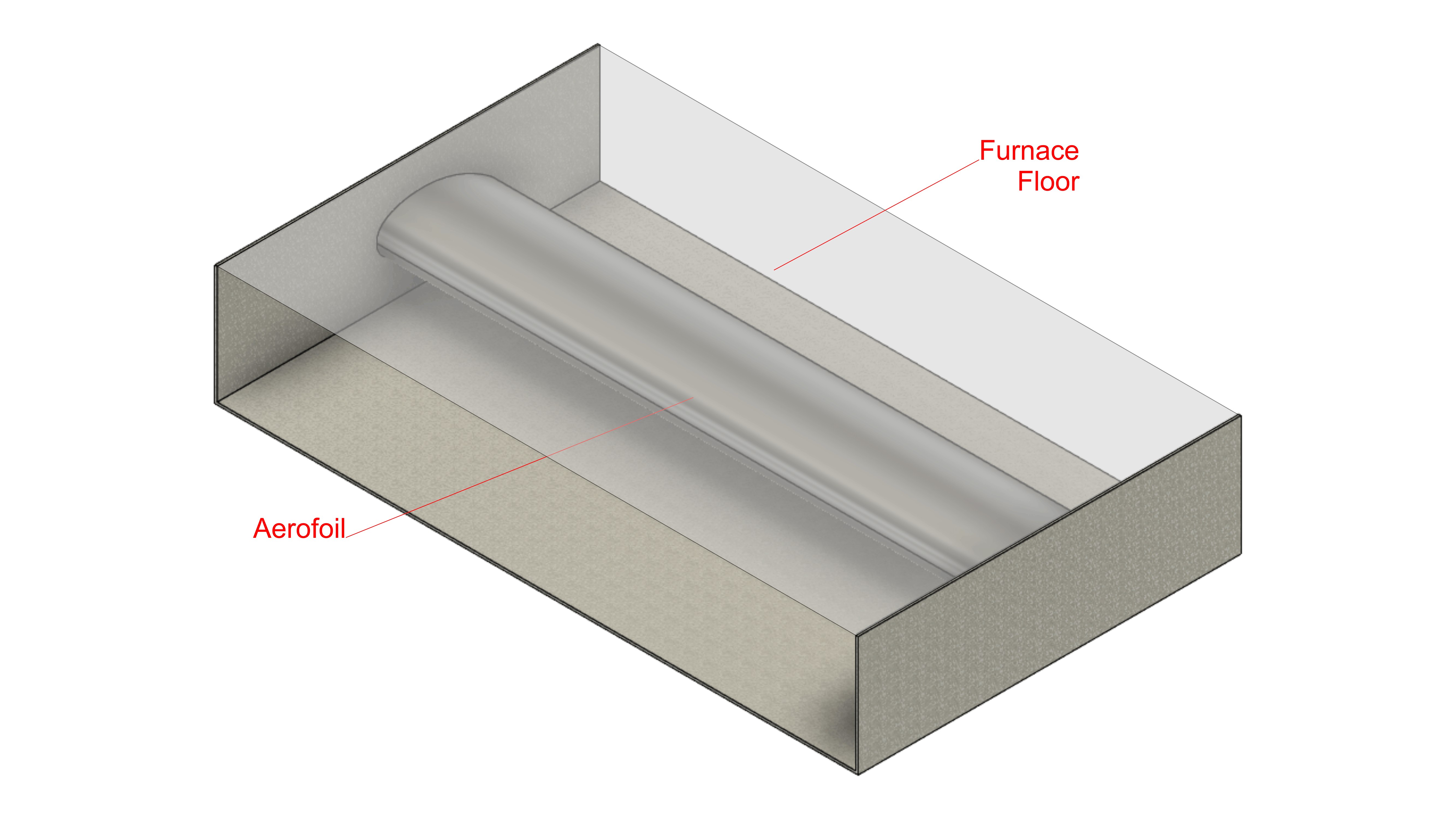

The combustion control system utilised an aerofoil located in the FD ducting under the furnace floor.

This generated approximately 40 mbar differential pressure and therefore reduces the air flow accordingly.

Solution

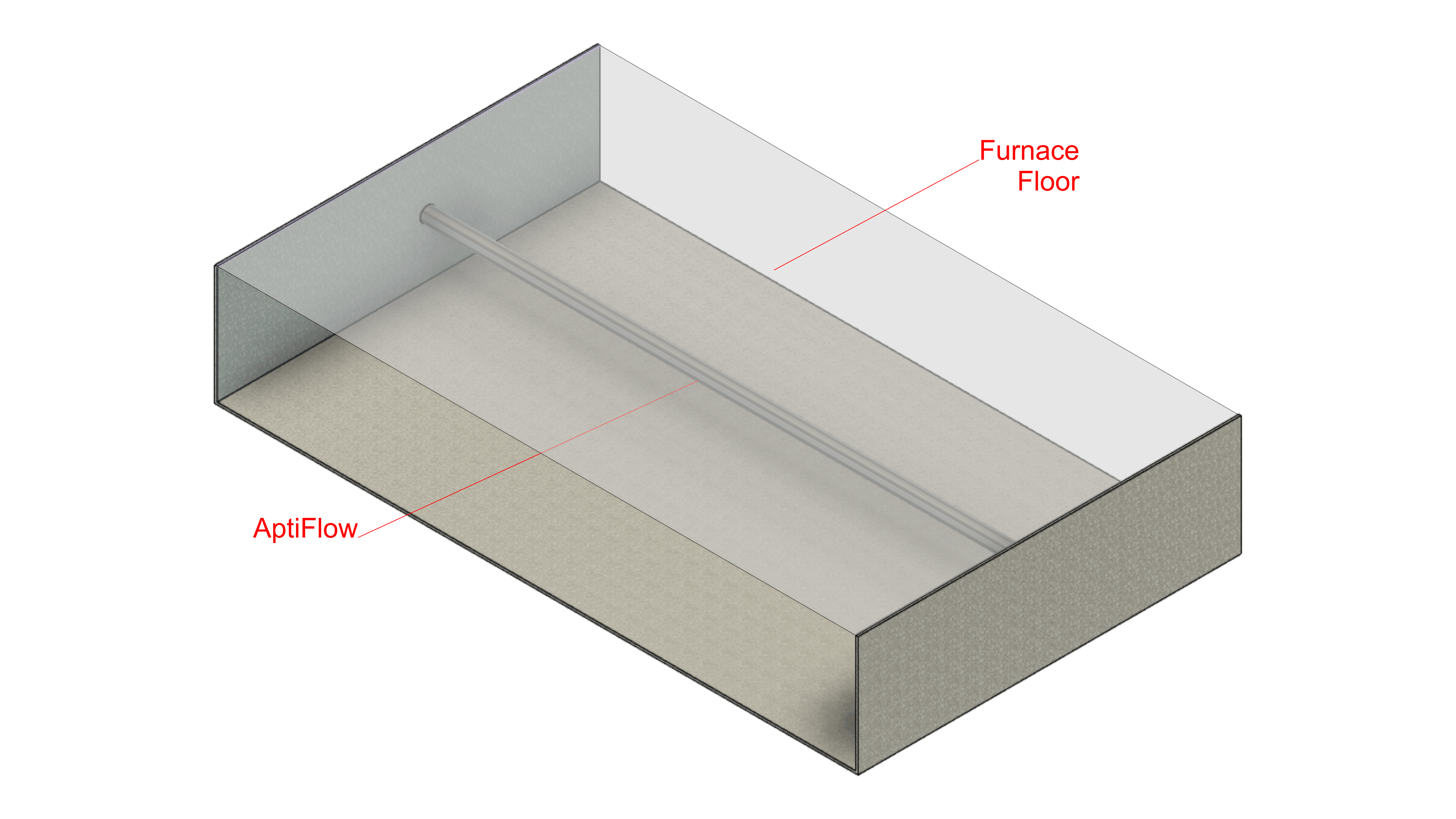

An AptiFlow probe was designed for the application with the resulting differential pressure for the same flow rates being less than 2mbar.

Removing the aerofoil and fitting the AptiFlow probe in its place reduced the back pressure caused by the Aerofoil and increased the air flow into the furnace, and also plant capacity.

Practical Considerations

Site expressed reservations regarding such a low Differential Pressure and the feasibility of controlling air flow rate reliably.

In order to allay their reservations the agreement was made to deliver the probe, oversee the commissioning, and “take the probe back” should it not work.

With the major duct dimension being just short of 4000mm, and therefore the probe length needing to be in excess of 4m it was decided to make the probe as a two-piece design – for ease of transport.

Performance Criteria

The probe was successfully installed, commissioned, and gave reliable service measuring 250,000 kg/h combustion air at 6 kPa G and 300° C in a duct with 3940mm x 1460mm internal dimensions.

Site ordered another two probes for two additional “sister” boilers performing the same duty – the best recommendation we could have recieved.