Ultra Large Bore

Solution to measure flow rate in 8.4m exhaust stackOverview

Aluminium Bahrain BSC (Alba) used our Aptiflows in one of the largest aluminium smelter sites in the world.

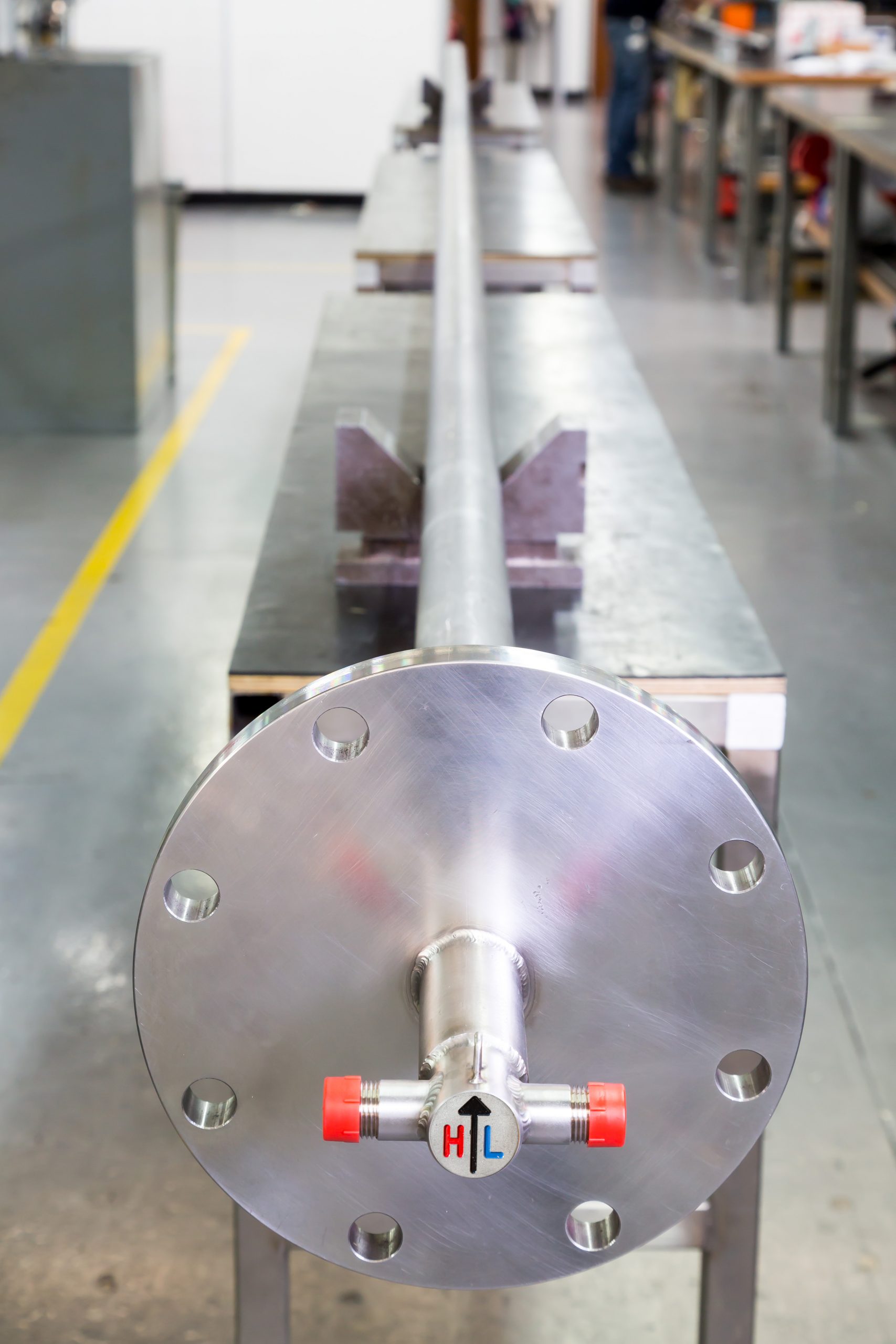

Our Aptiflows are installed in two chimneys in the Gas Treatment Centre’s outlet stacks on two diametrically opposed flanges (6 inches 150lb) on an 8.4 meter ID duct.

Application

Aluminium Bahrain (Alba) were faced with the task of measuring flow rates in excess of 1000 m3/s at temperatures up to 200 degrees Celsius in an exhaust stack that is over 8 metres in diameter.

Solution

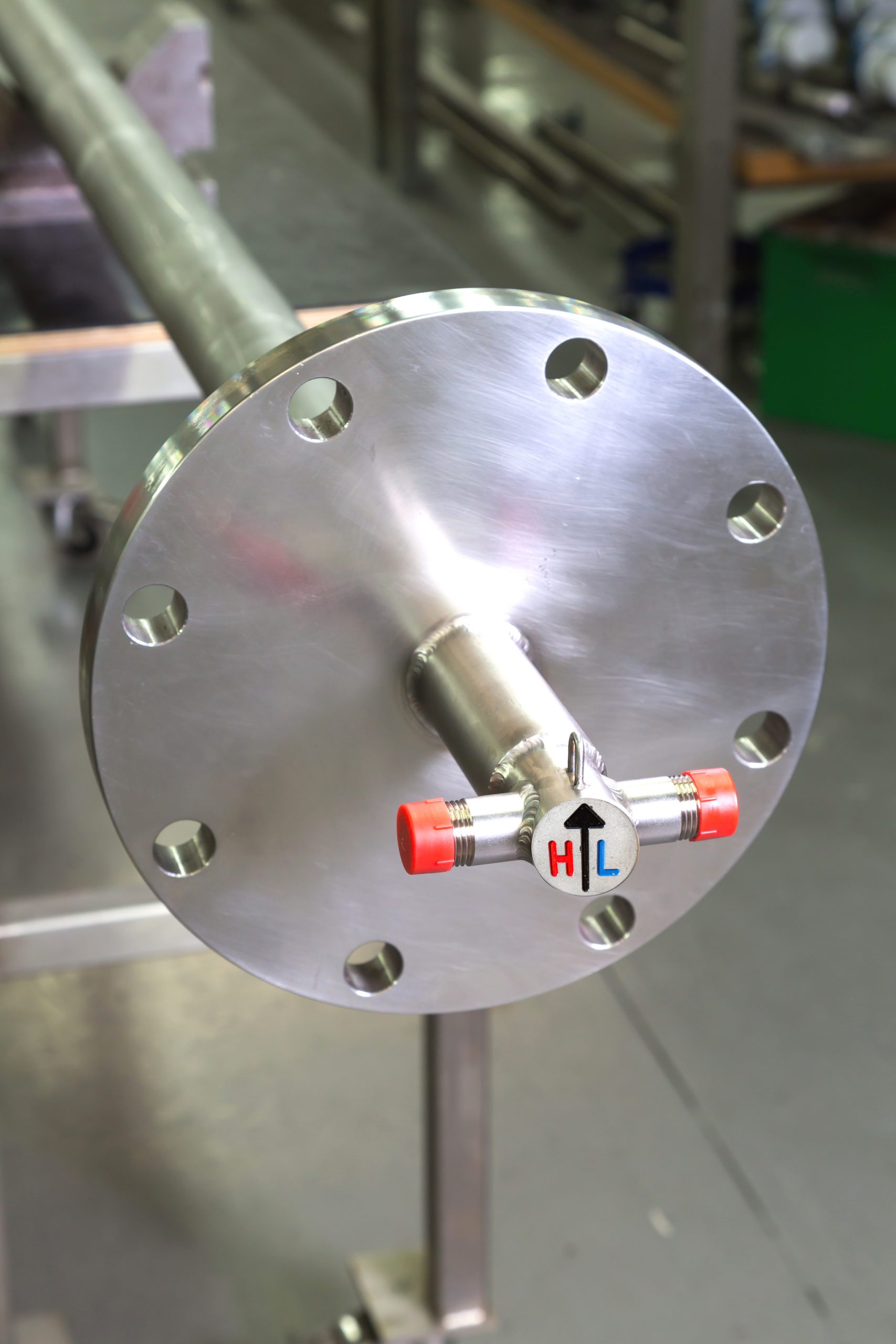

The requirement was met using an AptiFlow Averaging Pitot Tube which was supported at each side of the duct via 6” ANSI 150 LB Flanges.

One of the design features is the need to accommodate thermal expansion differential between the outer and the internal averaging tubes which was successfully overcome by use of expansion joints.

Technical Considerations

The AptiFlow is designed for an operating temperature in excess of 200° C. Under steady conditions this is no problem, and the bending moments for the support regime create stresses well within the allowable limits for the 316L St Stl. material of construction at the elevated temperature.

The more significant aspect, however, is startup and shutdown where thermal lag between the probe outer tube and the internal tubes may cause differential expansion rates.

In order to accommodate such occurrences internal expansion joints were used so that the independant growth and shrinkage of the tubes due to the temperature differences would be absorbed without mechanical stress.

No Difficulty in Manufacturing

The AptiFlows were manufactured by Endress+Hauser UK in their Wythenshawe workshops and fell easily into their normal production system.

Perhaps not as challenging as their multi-point temperature sensors, the probe remains memorable for its length and dynamic choreography employed manoeuvring it about the workshop.

Packing and Delivery

Finally, after manufacture, testing, final inspection, and documentation compilation – comes the packing and delivery.

Not exactly insignificant when the probe is in excess of 8m length – but also not too difficult a challenge with a dedicated workshop team having a natural “can-do” attitude.